Fa(c)t imagines a future where waste fats act as intelligent signals.

Embedded into infrastructures, policies, and materials that shape our energy and food systems.

At its core, Fa(c)t responds to a broken cycle: while waste oils and fats are vital for producing low-carbon biofuels, around 30% of the domestic supply is stolen, and the EU imports over 80% - with nearly half falsely declared as waste. Much of this is palm oil (POME) disguised as legitimate feedstock, disrupting circular economies and enabling unsustainable trade. Fa(c)t reimagines the outdated Victorian grease trap as a modular, responsive tool, transforming kitchens and waste sites from passive collection points into active nodes in a smarter, traceable waste system.

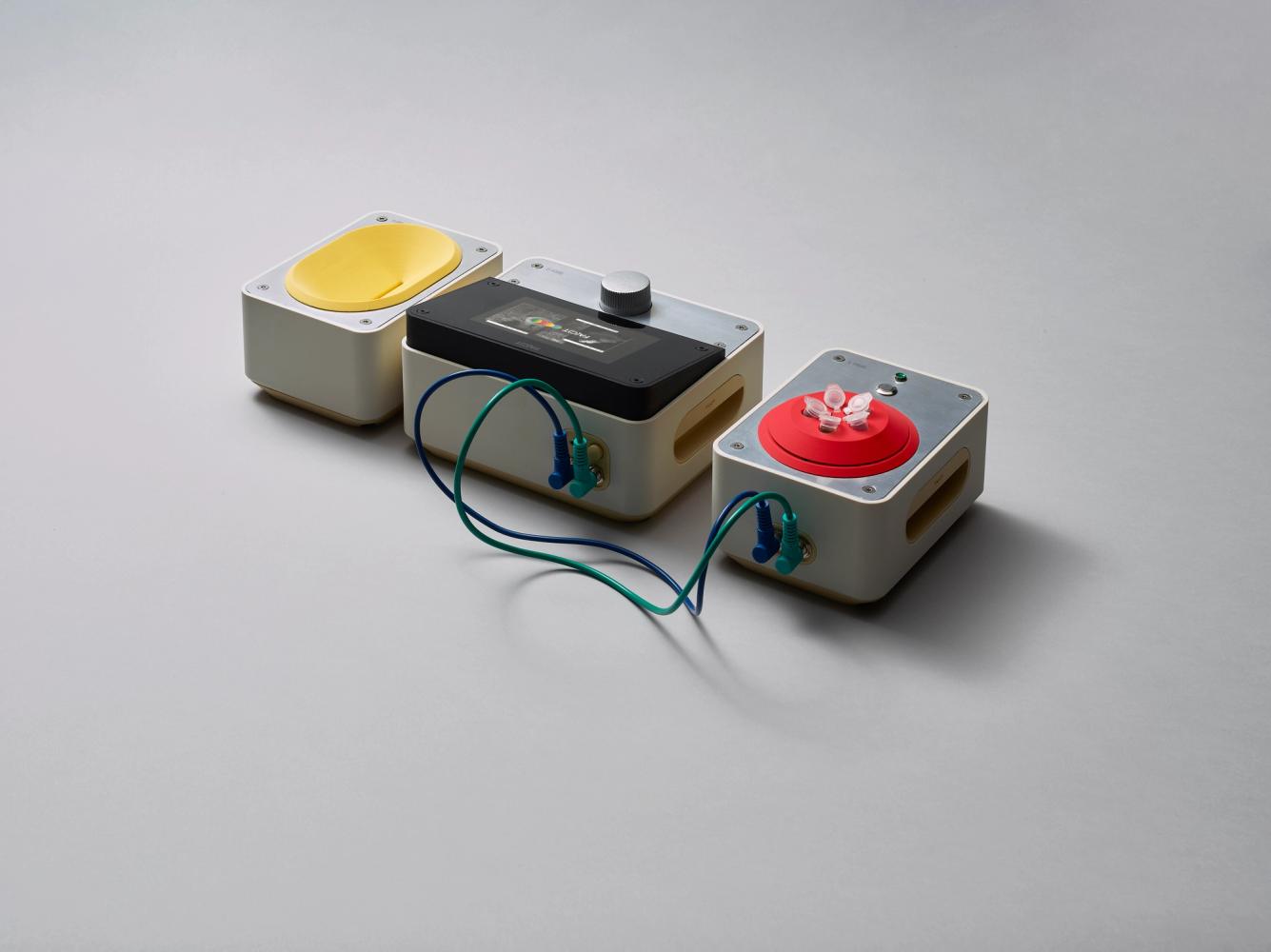

Fa(c)t has evolved into a working prototype and a catalyst for interdisciplinary negotiation - where design meets data, and material meets policy. It explores how machine learning and open-source sensors can detect illicit contaminants, trace fat flows, and support new material futures from waste oils and biofuel byproducts.

Speculative design Interventions from the Fa(c)t Platform

- Biochar Integration

Re-routing heavier fatty acid wastes to pyrolysis and biochar production, developed in collaboration with Eco-Clarity. Clay tiles were prototyped using fat-infused biomaterials. - Material Innovation

Advising on the reuse of byproducts like crude glycerol and wood flour from waste oil processing, Eco-Clarity experimented with fat-based plastics and site-responsive material manufacturing strategies. - Fat Security Framework

Introducing a traceability model using early-stage machine learning. Factories can train a 'fat dataset' to detect illegal contaminants and support trust-based waste economies.

As part of Fa(c)t’s ongoing evolution, FICTA Studio initiated a collaboration with Daniel Barnes, founder of Manufactured Design, to explore how speculative tools could translate into scalable, field-ready prototypes. Building on shared interests in decentralised systems and rapid fabrication, the partnership focused on reimagining the Fat Trap as a modular intervention suited to multiple environments—from commercial kitchens to industrial waste sites, blending live testing, on-site manufacturing, and community-led monitoring systems.